Know-how Know-how

Step 1

The sketch

The sketch is a first artistic drawing specially made to be suitable for our knitting machines.

The sketch

The sketch is a first artistic drawing specially made to be suitable for our knitting machines.

Step 2

Map setting

The drazing is then translated into digital date to be read by the machines.

Map setting

The drazing is then translated into digital date to be read by the machines.

Step 3

Warping

Raw materials are then coiled up on suitable supports for our machines.

Warping

Raw materials are then coiled up on suitable supports for our machines.

Step 4

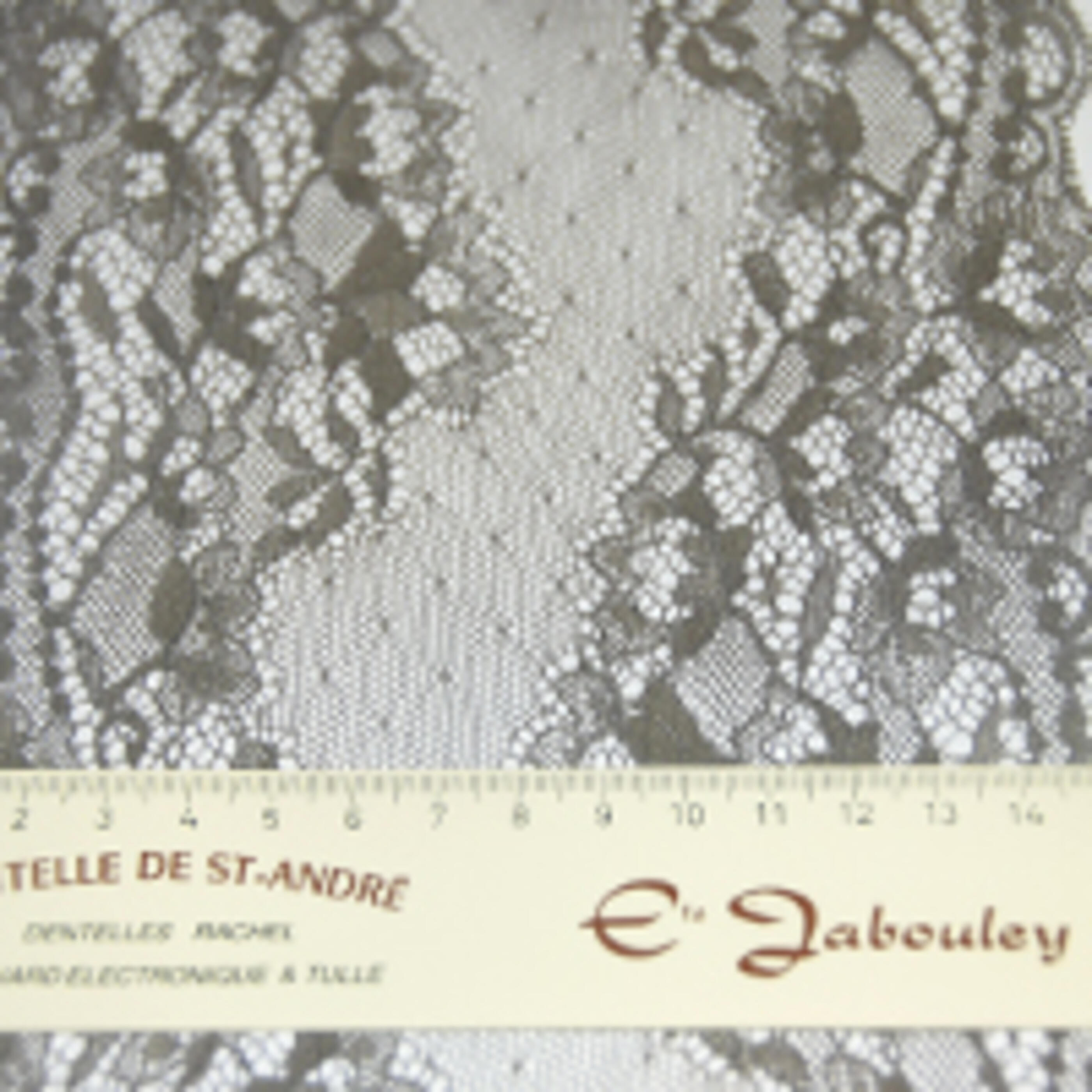

Knitting

Lace is made using the knitting technique, not weaving. Knitting is made up of loops, called stitches, passed through each other. The stitches are held on needles until they can be blocked by passing a new stitch through them. The knitting machines can welcome up to 10,000 threads!

Knitting

Lace is made using the knitting technique, not weaving. Knitting is made up of loops, called stitches, passed through each other. The stitches are held on needles until they can be blocked by passing a new stitch through them. The knitting machines can welcome up to 10,000 threads!

Steph 5

Grege control

Grege pieces are all controlled before being sent to the dye-house.

Grege control

Grege pieces are all controlled before being sent to the dye-house.

Step 6

Dyeing process

Laces are dyed according to our color range or can also be dyed according to customers' colors.

Dyeing process

Laces are dyed according to our color range or can also be dyed according to customers' colors.

Step 7

Quality control

Coming back from dyeing, every lace ic controlled according to precise specifications: color conformity, disgorging, width, dimensional stability, etc...

Quality control

Coming back from dyeing, every lace ic controlled according to precise specifications: color conformity, disgorging, width, dimensional stability, etc...

Step 8

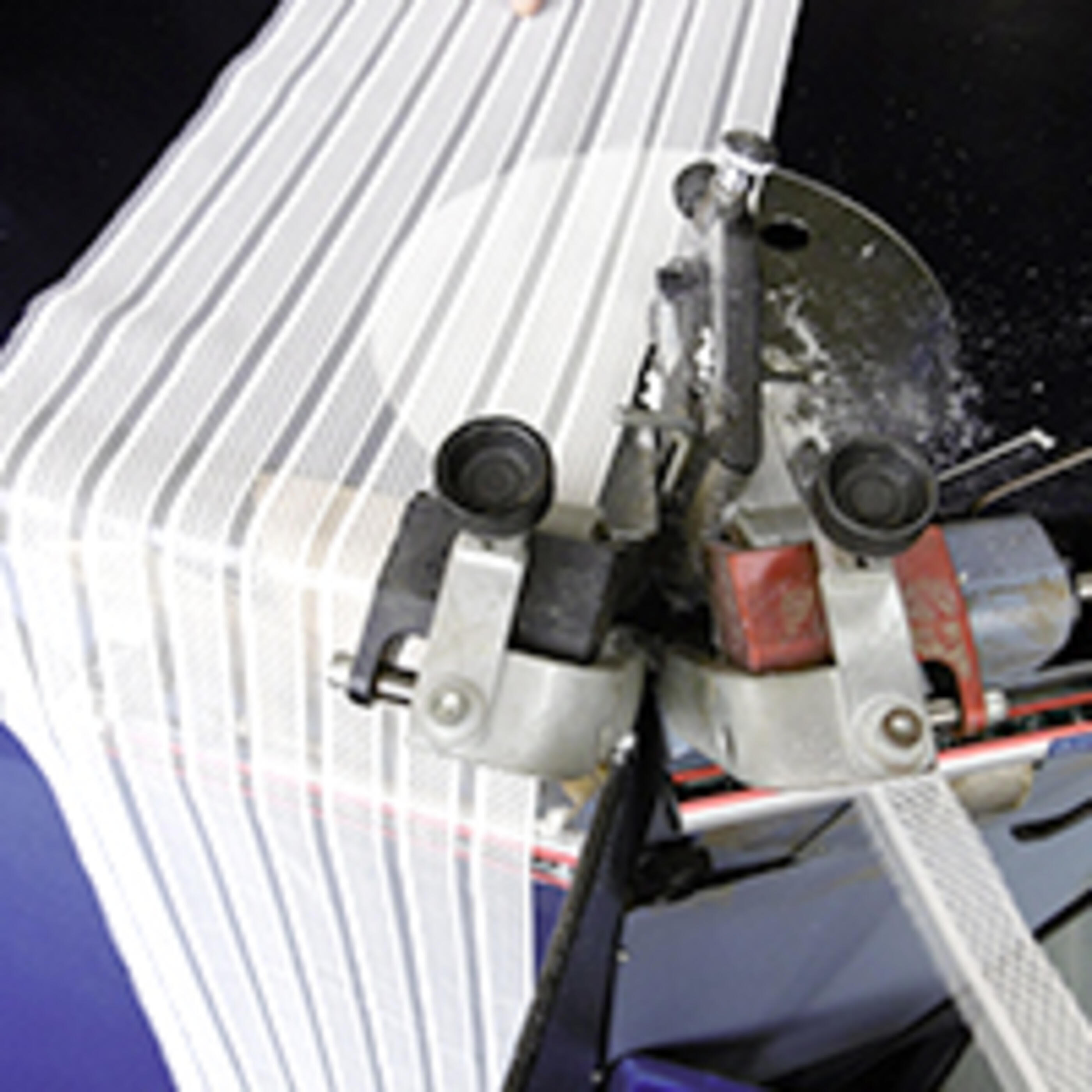

Cutting the ribbons

The lace cutting operation can be performed by different techniques, either with machines or manually too.

Cutting the ribbons

The lace cutting operation can be performed by different techniques, either with machines or manually too.

Step 9

Control and Packaging

Before shipment, all our qualities, including ribbons and allovers are being controlled.

Control and Packaging

Before shipment, all our qualities, including ribbons and allovers are being controlled.

Step 10

Our stock

The 300 references of our collection are always available in Black, White and Cream, as well as in each color of their own color range.

Our stock

The 300 references of our collection are always available in Black, White and Cream, as well as in each color of their own color range.

Step 11

Sampling

The sampling service allows our customers to have a very quick illustration of the desired products.

Sampling

The sampling service allows our customers to have a very quick illustration of the desired products.

Step 12

Shipment

Thank to our large stock, shipments are made on the same day the customers place an order with us.

Shipment

Thank to our large stock, shipments are made on the same day the customers place an order with us.